Plate ice applications:

● Aquatic product processing, cooling,preserving and transportation

● Edible ice making factory

● Port ice making factory

● Chemical projects and dye cooling and temperature reduction

● Medical treatment and medicine

● Cooling, temperature reduction and preservation, etc.

● Cold storage central air conditioner

● Cold water temperature reduction system

Plate ice machine conditions:

Electrical require: Full electric system complyingWith the general international standard

Standard condilion:

Water inlet temp.16℃Amibenttemp. 25℃

Application condilion:

Ambient temp.5℃~40℃ water temp. 5℃~35℃

Special condition:Ambient temp.-30℃~60℃ water temp.5℃~46℃

Ice thickness: 10~12mm

Refrigerant: R717、R22 、R404A、R507A

Plate ice machine evaporator feature:

Plate ice evaporator mainly fall into two kinds, namely, aluminium alloy plate ice evaporator and stainless steel plate ice evaporator. Plate ice evaporator adopts direct expansion systems and use R-22, R507A, R404A or ammonia (NH3) as the cooling medium.

——1 Evaporator manufactured with special technologies

The 735mm*1445mm large-sized evaporator is manufactured of pure stainless steel with the world's most sophisticated laser-welding technologies. It boasts such advantages as sanitation, cleanness and no harm to human body, etc. It fully conforms to the certification requirements of HACCP and FDA and can be applied to the fields in relation to edible ice. It contains a number of evaporators in parallel connection and can produce 500kg to 600 tons of ice per day. Water circulation system Aluminium plate ice evaporator Stainless steel plate ice evaporator.

——2 Special water circulation system

The raw material water flows evenly on the surface of the evaporator, and gathers into the water tank through the special water trough at the bottom of the evaporator. Then the water is pumped to the water distributor in the top of the evaporator and returns to the surface of the evaporator to freeze. The said special water circulation system makes the surface of plate ice produced very smooth.

——3 Mode of peeling ice at a high speed and without additional heat

It's unnecessary to introduce hot gas from outside since the hot Freon gas produced by the plate ice machine itself is fed into the plate ice evaporator. Then within less than 1 minute the plate ice that has already taken shaped falls down and breaks becaus e of the pull of gravity.

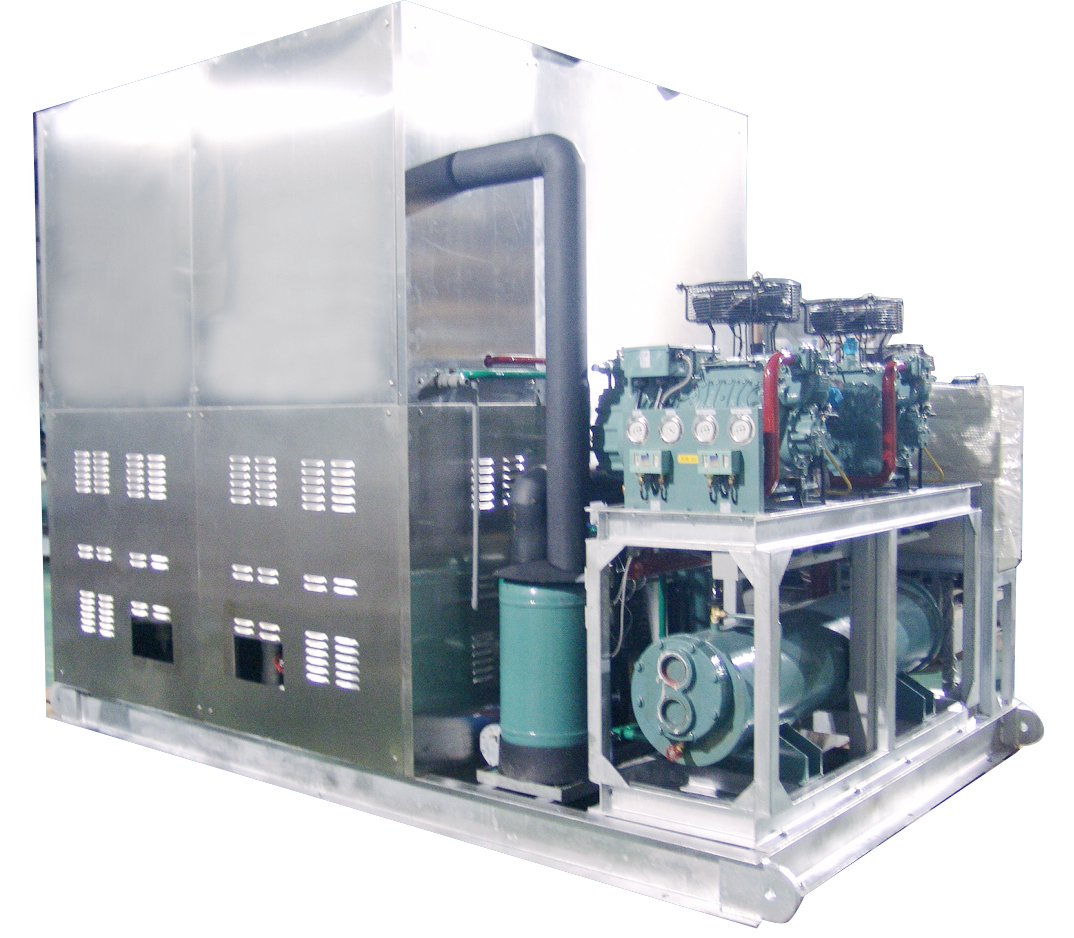

——4 Modular design

The machine body adopts steel welding and galvanized structure, which boasts anti-corrosion, high stability, and can ensure good running in various hard working conditions. The machine service life is thus proIonged,and the maintenance cost is accordingly reduced

Plate ice machine Models available:

Model(PIM) | UKPI-1AF | UKPI-2AF | UKPI-3WF | UKPI-5WF- | UKPI-6WF | UKPI-8WF | UKPI-10WF | UKPI-15WF | UKPI-2OWF | UKPI-30WF | UKPI-40WF | UKPI-100WF |

Ton/Day(ton) | 1 | 2 | 3 | 5 | 6 | 8 | 10 | 15 | 20 | 30 | 40 | 100 |

Machine Structure | Complete machine set | Evaporator compressor unit | ||||||||||

Thickness(mm) | 10-12 | |||||||||||

Length(mm) | 1530 | 1987 | 1987 | 2450 | 2450 | 3900 | 2110/2200 | 2900/1600 | 3620/2700 | 2900*2/2700 | 3620*2/2700*2 | 3620*5/2700*5 |

Width(mm) | 1160 | 1510 | 1440 | 1890 | 1890 | 1520 | 1700/1250 | 2200/1810 | 2200/2200 | 2200/2200 | 2200/2200 | 2200/2200 |

Height(mm) | 1700 | 1900 | 1990 | 2185 | 2185 | 2425 | 2385/1270 | 2390/1360 | 2490/2190 | 2390/2190 | 2490/2190 | 2490/2190 |

Cooling water (DN) |

|

| 40 | 50 | 50 | 65 | 80 | 80 | 100 | 100 | 125 | 200 |

Raw water inlet(DN) | 15 | 15 | 25 | 25 | 25 | 25 | 25 | 40 | 40 | 50 | 50 | 65 |

Water drain(DN) | 25 | 25 | 25 | 25 | 25 | 50 | 50 | 40 | 40 | 50 | 50 | 65 |

Power supply cable port(mm) | 40 | 40 | 40 | 40 | 40 | 40 | 40 | 40 | 40 | 50 | 50 | 70 |

Net weight(kg) | 1000 | 1300 | 1600 | 2000 | 2000 | 2500 | 2500 | 2700 | 3000 | 5400 | 6000 | 15000 |

Compressor power (HP) | 5 | 8 | 12 | 25 | 30 | 40 | 50 | 60 | 80 | 120 | 160 | 400 |

Ice machine pump power(kw) | 0.1 | 0.25 | 0.37 | 0.55 | 0.55 | 0.75 | 1.1 | 1.5 | 2.2 | 2.2 | 4.4 | 8.8 |

Crusher power(kw) | 0.37 | 0.55 | 0.55 | 0.55 | 0.75 | 0.75 | 0.75 | 0.75 | 0.75 | 1.5 | 1.5 | 4.0 |

Evaporator | 2 | 4 | 6 | 10 | 12 | 16 | 20 | 32 | 40 | 64 | 80 | 200 |

Charged refrigerant(kg) | 15 | 20 | 30 | 40 | 40 | 55 | 60 | 100 | 140 | 220 | 280 | 600 |

Disclaimer:

All photos and specifications Uruk offered are just for customer general reference, and we have right to change or update without notice. Please confirm all information before placing an order.